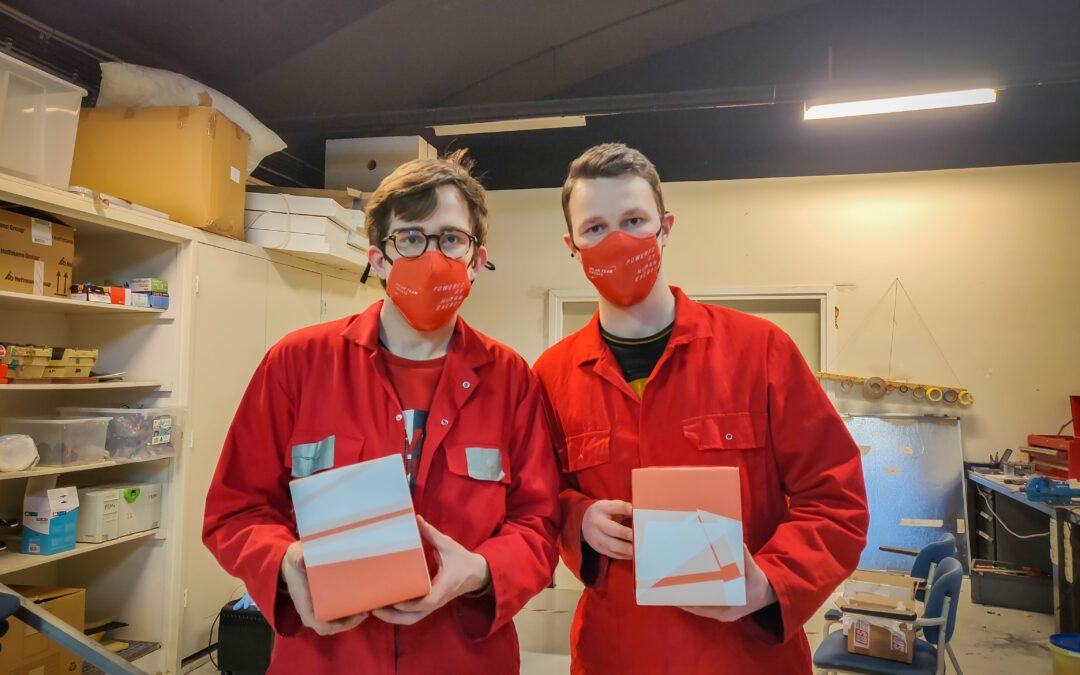

Photo by Camiel Lemmens

EN | NL

Team 2021 faced many challenges on their way towards the Bridgestone World Solar Challenge 2021. Five months have passed already in which the team focused on creating the most efficient solar car possible. Now the design phase is over and the shape of the car is finalised. This week’s sub-team is Mechanics Subteam. Before we reveal the design to you, we will dive into how the different technical sub-teams experience this phase, what challenges they faced and which challenges are ahead.

What is the mechanics sub-team doing?

Paul: “In short, the Mechanical Engineers work on the solar car parts that can move. For example, we design the suspension, steering system and the solar charging configuration (read more here). To produce a world-winning solar car, we work together closely with all other technical sub-disciplines. After all, our parts have to fit into the shape of the car which the Aerodynamics Engineers design.” This year’s Bridgestone World Solar Challenge regulations open up the possibilities of a different kind of car. For example, 3-wheeled cars are allowed again and PVC Pat was introduced, a manikin that has to fit into the car. Weighing up the pros and cons, running simulations and discussing the different possible car shapes made “having enough time” the biggest challenge of the mechanics sub-team.

How did it all start?

No one of team 2021 has ever built a solar car before – so where do you start? On their first day in September, the technical team sat together and was wondering where to start. “The possibilities seemed endless, and we decided to list the tasks we knew of and just divide them. Only after some time, we got into a working rhythm that was very much needed for the difficult moments yet to come.”

Why is it so difficult to build a solar car?

Building a solar car is nothing you do regularly during your university courses. But, the university equipped them with the knowledge and skills to design the different parts of the car. Their challenge comes with the complexity of the project: all parts have to be combined and still work together. Therefore, good communication is key. Not only among the sub-teams but also among the two mechanical engineers. The software used are not always up to the pace of the team, who are designing a car in a couple of months. To avoid confusion or lose progress, they had to figure out a good way of working: when can you open a file and when do you let someone else know that you changed something?

Next steps

All their hard work will be rewarded soon. Next up is an event some team members have been looking forward to since they applied in March 2020. During the Mock-up Test Session, the Mechanical and Electrical Engineers will test the concept they have been developing during the design phase in action. “Whenever a new mechanical part of the car arrives at the office, I know that my efforts have already been more than worth it” says Paul. These lightweight and durable parts are certainly something to be proud of. We cannot wait to show you how everything looks put together during our car presentation later this year!

Follow us on Instagram, Facebook, Twitter, or LinkedIn to stay up-to-date!

Recent Comments